Successfulness

At JDK Group,

we bridge the world with Bangladesh. Since 2009 we have been working in the RMG industry catering for our many valued customers with efficiency, honesty and reliability.

BUSINESS PORTFOLIO

Our passionate team of fashion designers, technicians, photographers creates each design line for different customers according to their individual taste and their customer range. We convert the concepts into sketches and by choosing the trendy colors for yarn and fabric. Our Graphic team creates graphics and patterns by watercolor, pencil, photography and 3d illustrations. These sketches and colors are sent to our design sections in BD and China. We always take inspiration by attending fashion shows, fairs and shopping. We constantly update our collections with the trend. We always keep joining bellow

- PITI UOMO

- Bread&Butter

- PANORAMA, Berlin

- CPD, Dusseldorf

- Magic Show, Las Vegas

We also shop all over US and EUROPE and constantly follow fashion magazines and online fashion blogs. We give our best efforts to offer the exclusively customized products to our clients.

Trendy Design

Collections

We strive at JDK to be ahead of time and be the trendsetter. We produce our own collections every season (AW/ SS) with a range of styles that comprise garments for all gender and across all ages.

Our collections are always comprises the latest/upcoming yarn, accessories, colors and of course designs.

We offer samples in both Manuel and Jacquard knits. We also develop samples/designs given to us by our customers as per their requirements.

Merchandising

Our well-trained and capable teams of merchandisers are working around the clock to give our customers all the support they need. Starting from procurement stage of yarn, fabric, lab-dips, hand-looms, trims till the finished products are shipped.

We have 40 stuffs in merchandising team, divided in to 5 divisions in JDK head-office to attain our valued customers.

State of the art machinery of transnational configuration is our pride. Beside this the dedication of men and women operating the machines, whose skills and expertise are devoted to match our customers’ quality specifications and on time delivery of the sweaters of international stature.

Our all units are 100% compliance and certified by reputed authorities like BSCI, SADEX, AC-CORD, OEKO-TEX, ITX, WRAP, etc. We strictly follow a NO CHILD LABOUR Policy. As well as all other Laws and regulations set by the Bangladesh Govt. such as HEALTH AND SAFETY, MEDICAL FACILITY, BUILDING STRUCTURE etc.

Our total factory working floor is more than 160,000 Sq-ft(4 floors), with additional space for canteen and prayer hall. We have a total of 2300 sets of knitting machines compiling all Gauges from 3gg to 12gg, and 800 sets of linking ma-chines covering all gauges.

Our approximate total production capacity is 25,000 Dzn per month comprising all gauges. out of which 15,000 Dzn in 12gg per month.

Production

We have taken sourcing our product from compliant factories who maintain social compliance, technical compliance and supply chain management. Our compliance manager and quality manager monitor closely and review quarterly based on compliance issues.

For monitoring and handling of production, more than 150 employees like merchandizer, quality team is doing work to executive production.

We have capacity to handling 1700,000pcs of sweater, woven and knit in a year.

We have separate design section in each factory for production and R&D.

Quality Control

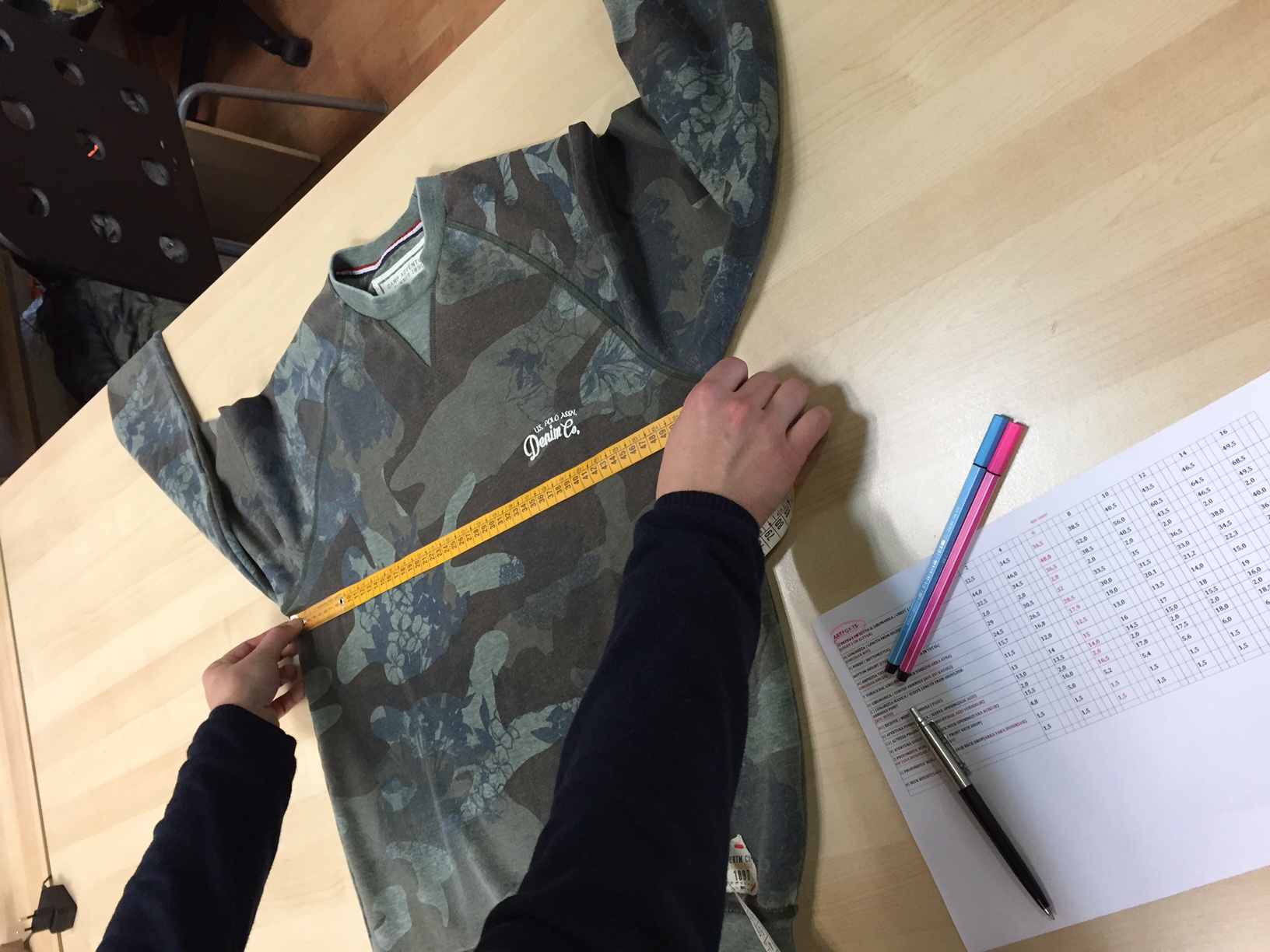

Our focused and well trained QA teams are working in every key check point of the manufacturing stages to attain the customers required quality standards. Starting from sample approval to the final production stages, our QCs are always monitoring and supervising the factory people. To achieve the stiff target of attaining the high standards, we allocate individual QA teams for individual clients, working around the clock in every factory we produce at.

These teams at the factories are centrally monitored and regulated by the QA department stationed at JDK Fashion head office on a daily basis. Consequently, our efficient quality control system has enabled us to meet the AQL standards set by the clients.

In order to better ourselves, we have developed a chain of procedures to ensure our required standards are met to maximize production and minimize wastage. And this also ensures on time shipment according to plan.

- Understanding the customers’ quality requirements.

- Organizing & training quality control department.

- Ensuring proper flow of quality requirements to the QC department.

- Ensuring proper flow of quality requirements to the Production Department.

- Establishing quality plans, parameters, inspection systems, frequency, sampling techniques etc.

- Inspection, testing, measurements as per plan.

- Record deviations

- Feedback to Production Department.

- Plan for further improvement.

We push ourselves to the limit to make sure that the chain of procedures mentioned above are followed every time for every order.

Business Ethics & Compliance

Our prime objective is to build a transparent bridge between our customers and us for building and maintaining a long-term relationship.

All our nominated manufactures are 100% compliance. Most of our factories are certified by globally recognized auditing companies. Over the time we have accumulated BSCI, SEDEX, WRAP, ACORD, OEKO-TEX, ITX, WALMART etc.

We have internal compliance teams stationed to keep up the compliance standards mentioned above regularly. These teams report directly to our central Compliance Department stationed in JDK head office.

Our highly experienced team of 10 commercial/logistic is working continuously to arrange all the documents required from receiving an order from the client to shipping the final goods. We have our own logistics to support a smooth transportation of raw material and shipping goods to ports.

We are well experienced in shipping mode such as sea and air. We work on FOB/CIF/FCA/DDP. Our terms of payments are LC and TT.